COMPATIBILITY

All RA-series regulators are suitable with all gasoline types including unleaded, leaded, oxygenated, and pre-mixes. Furthermore, they are compatible with alcohol blends of fuel including methanol, ethanol, and E85.

OVERVIEW

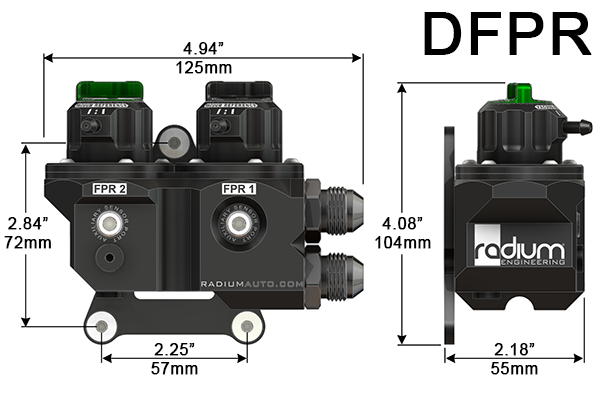

The Dual Fuel Pressure Regulator (DFPR) simultaneously isolates 2 separate fuel systems.

This can be very advantageous in the following scenarios:

- Modern engines that use both direct injection and port injection.

- Modern venturi transfer systems that are incompatible with fuel surge tanks.

INDEPENDENT INSTALLATION VIDEO

FUEL PRESSURE ADJUSTMENT

RA-series regulators feature the first tool-less pressure adjustment. A jam nut and set screw are no longer required. With a simple turn of the knob, pressure will be increased or decreased. Additionally, there are no inherent air (vacuum/boost) leaks through the threads that traditionally a smoke detector would pick up.

To aid in adjusting pressure, there are incremental detents that provide haptic feedback to the user. Every detent permits 1psi (+/-0.5psi) of adjustment depending on current fuel pressure.

NOTES

- FPR2 pressure will always be equal to or less than FPR1 pressure. It cannot physically be higher.

- If rising rate pressure pushes FPR2 higher than FPR1 is set, FPR1 will increase to match FPR2.

FUEL PRESSURE STABILITY

With years of track and bench testing data, the RA-series regulators have been refined to optimize pressure management. A newly designed single stainless steel return orifice generates laminar flow that enhances stability control.

Minimum Pressure: 18.5psi (1.3bar)

Maximum Pressure: *N/A

*This is rhetorical. The maximum pressure is dependent on the relief valve inside the pump or the maximum current the fuel pump controller allows.

ABOUT FUEL PRESSURE DROP AFTER SHUTOFF

Some installations may experience a rapid fall of fuel pressure when the engine and/or fuel pump shuts off. This is considered normal operation for aftermarket fuel pressure regulators, regardless of brand.

This can occur due to the diaphragm seat and the return orifice not fully sealing when fuel flow is stopped. For regulators to have the ability to regulate high fuel flow rates, the size of these components must be increased. This creates larger sealing surfaces between the components, preventing them from forming a perfect seal, even with high spring rates. This is not an indication of an issue or defect and it is not a cause for concern on its own. You do NOT need to contact technical support about this issue. Fuel pressure will reset immediately when the fuel pump is activated again.

If the engine is experiencing other symptoms such as long cranking to start, or delays in pressure building when cranking, these symptoms are unrelated to the regulator. There is likely an issue with the fuel feed hose draining back to the tank. This is most likely due to an internal leak somewhere in the pump module: possibly a venturi jet pump, or the lack of a fuel pump check valve.

1:1 RISING RATE VACUUM REFERENCE

RA-series regulators feature a 360 degree swiveling vacuum reference port that is double O-ring sealed. This is the first in the industry. It permits the installer to quickly point the vacuum fitting in any direction with no tools required.

There are 4 interchangeable 10-32 threaded vacuum port fittings provided to cover all scenarios.

- Barbed Fitting: A black zinc-plated 3/16' (5mm) barb machined from high strength steel that is compatible with the following vacuum hoses: 5/32' (4mm), 3/16' (5mm), and 7/32' (6mm)

- 3AN Male Fitting: A black zinc-plated adapter machined from high strength steel that is compatible with 3AN hose ends

- Push-To-Connect: A nickel-plated brass fitting with Buna-N O-rings that is compatible with hard plastic 1/4' OD tubing

- Vacuum Plug: A black oxide stainless steel screw that is used to maintain a constant (non dynamic) fuel pressure. Beginning in the mid 1990s, vehicle manufacturers started transitioning to returnless fuel systems to lower EVAP emissions. To keep temperatures lower, these regulators are mounted inside the tank and do NOT have the ability to be vacuum referenced. This plug would be required in this scenario.

NOTE: When installing the vacuum fitting, it is recommended to use a wicking medium-strength thread locker.

SPECS & FEATURES

The DFPR is designed to be plumbed upstream (before) the HPFP and port injection fuel rail(s).

PUMP IN

Threads: 3/4-16" (8AN ORB)

This port is the only inlet. The low pressure fuel pump (LPFP) outlet should be plumbed to a low micron fuel filter and then secured to this port.

FPR1 OUT

Threads: 3/4-16" (8AN ORB)

This port should be plumbed directly to the high pressure fuel pump (HPFP) inlet.

FPR2 OUT

Threads: 3/4-16" (8AN ORB)

This port should be plumbed directly to the port injection fuel rail(s). Plug the opposing end of the fuel rail(s). NOTE: If the engine does not have port injection, this port can be plugged with no affect to FPR1. For FPR1 to work efficiently, spin the FPR2 knob fully counterclockwise.

RETURN

Threads: 3/4-16" (8AN ORB)

This port should plumb directly to the fuel tank (or fuel cell). NOTE: If there is no return port on the fuel tank, these barbed hose adapters may be an option to return fuel into the filler pipe.

AUXILIARY SENSOR PORT (FPR1)

Threads: 1/8"-27 NPT

To monitor FPR1, this ports can be used for gauges, sensors, etc. A plug is included.

AUXILIARY SENSOR PORT (FPR2)

Threads: 1/8"-27 NPT

To monitor FPR2, this ports can be used for gauges, sensors, etc. A plug is included.

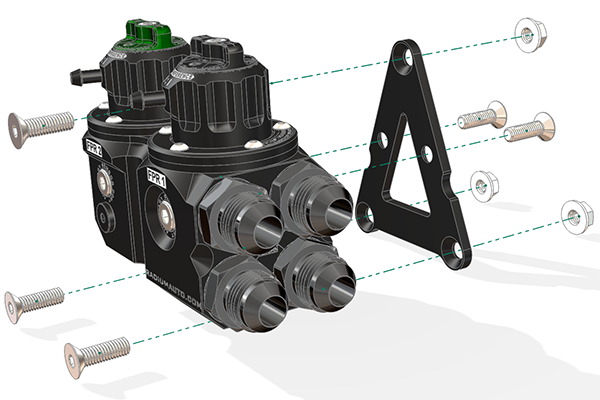

INCLUDED

- Main DFPR Rotating Assembly

- Mounting Bracket with Hardware

- 5mm Barbed Vacuum Fittings

- 1/4' Push-To-Connect Vacuum Fittings

- 3AN Male Vacuum Fittings

- Vacuum Plug Fittings

- 8AN ORB to 6AN Male Fittings

- 8AN ORB to 8AN Male Fittings

ADDITIONAL IMAGES

DFPR, Dual Fuel Pressure Regulator

- Regular price

- Sale price

- $0.00

- Regular price

-