For many years Radium Engineering has been touting the benefits of a fuel pulse damper (FPD) in fuel injected systems. Formerly only seen on OEM fuel systems, Radium Engineering was the first to introduce the FPD to the high-performance aftermarket in 2015.

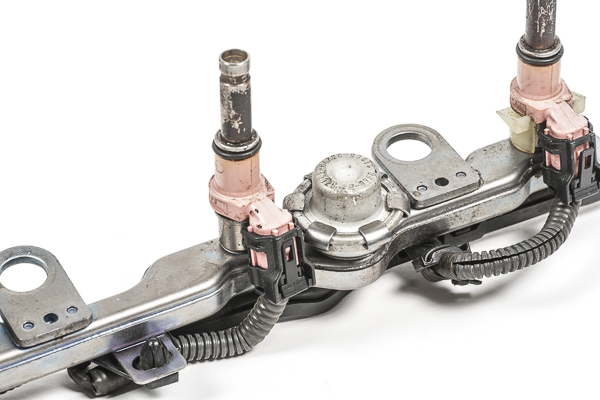

An often overlooked fuel pulse damper on an OEM fuel rail

OEM-grade fuel pulse dampers are specifically designed for the factory fuel system parameters. When modifications are made to the fuel pump, fuel rails, injectors, etc. these dampers are no longer as effective, or they must be removed for modifications to be carried out. Radium Engineering fuel pulse dampers are designed for use with high performance fuel systems, so damper benefits can still be realized.

What does a fuel pulse damper do?

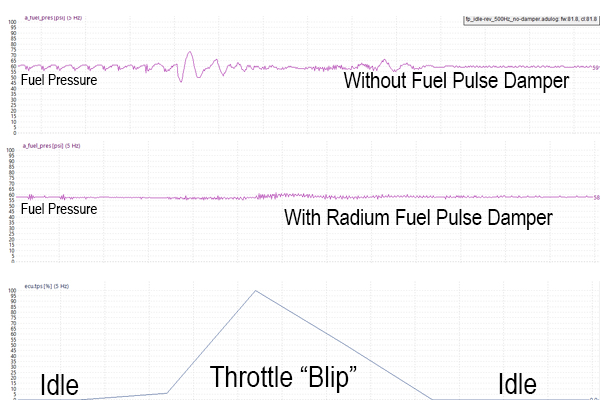

An FPD is used in fuel injection systems to attenuate (absorb) pressure pulsations generated by the fuel pump and by the injectors opening/closing. These hydraulic pulses can cause an undesirable noise, which can be transmitted to the passenger compartment. Under certain circumstances, they can even cause issues with fuel delivery to the engine. These pulsations can sometimes be large enough to hear and feel, but are often undetectable with a liquid-filled analog mechanical fuel pressure gauge because they happen so quickly. To truley "see" fuel system pulses, fuel pressure data logging must be done with a high quality fuel pressure sensor and a sample rate of approximately 500Hz.

The fuel pulse damper works by allowing the volume of the fuel system to change slightly to absorb the pulses. This is done with a spring-loaded flexible diaphragm inside the damper.

Below is a graph showing fuel pressure fluctuations on a 4-cylinder engine, with and without a Radium fuel pulse damper installed.

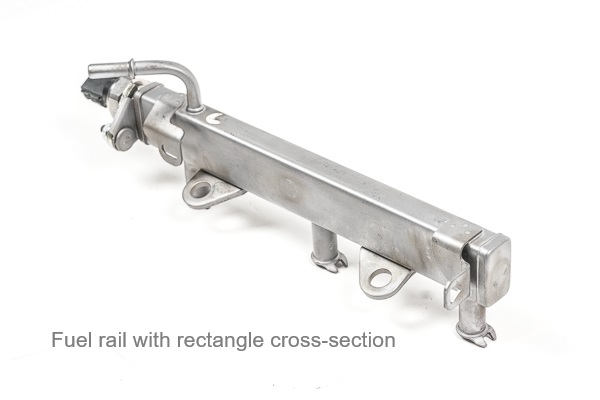

Most OEMs will utilize some method to attenuate the pressure pulsations. Manufacturers never prefer to add cost to a vehicle, so in some cases, instead of a fuel pulse damper, you may find some other methods employed to attenuate the noise. These measures can include rectangular cross-section fuel rails with a carefully tuned width and height, strategic location of the fuel pressure regulator, fuel lines mounted to the body using vibration isolating mounts, etc. For some OEMs, the noise is not an issue and there are no negative effects on fuel delivery, so no measure is taken to address fuel pulsations. It is different from application to application.

How do I know if I need a Pulse Damper?

As mentioned earlier, fuel system pulsations can have an undesirable effect on cabin NVH (noise vibration and harshness) by causing fuel line "knocking". They can also contribute to uneven fuel delivery and mysterious lean spots that are difficult to tune out. These are often the result of the hydraulic pulses acting in harmonic resonance with the injectors opening and closing. This issue can be aggravated by high-flowing aftermarket injectors. In some vehicles, these lean spots can result in stumbling during acceleration, commonly occuring in the 3k-5k RPM range. If you are experiencing any of these issues, a damper could be a good solution.

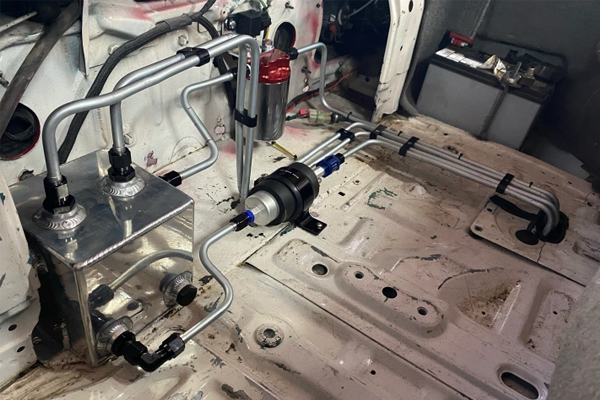

Furthermore, a fuel system that is plumbed with mostly hard metal tubing will be more susceptible to knocking and pulse issues than a system made with flexible rubber fuel hose.

While hard lines may look nice, they are echo chambers for fuel pulsations

Its not JUST about the noise. Most EFI tuners are not concerned with the noise, but rather with engine performance and seek constant, reliable fuel delivery throughout the RPM range in order to optimize the EFI tuning.

If everything is running great, and fuel delivery is spot-on and there is no fuel line knocking noises, then a damper would not provide any benefit to the system.

A damper IS NOT a magical "cure-all" for any fuel system problem or tuning issue!

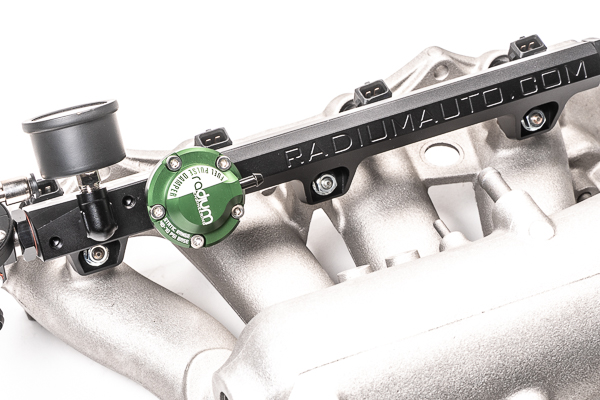

Nissan R35 GT-R fuel rails with Radium fuel pulse dampers installed

Which Damper do I need?

When it comes time to selecting a Radium fuel pulse damper, there are two decision that have to be made:

1. Tall or short version

2. Connection type (threads)

The green-top short (FPD-R) is perfect for static fuel pressures up to 70psi. It also fits into small spaces.

The black-top tall (FPD-XR) is great for vehicles with higher static fuel pressure, up to 105 psi.

If you have the space, the FPD-XR offers a wider frequency response and could be more effective at absorbing pulses.

Connection type will depend on how the damper will be plumbed into the system. Choose a direct mount of the fuel rail has a compatible threaded port. Radium offers "direct mount" dampers with 8AN ORB and 3/8NPT threads.

Note: All Radium fuel rails use 8AN ORB threaded ports.

Where do I install a damper?

It is preferred to mount a damper as close to the source of the pulsations as possible. This usually means mounting a damper directly on the fuel rail. If your fuel rail has an available female 8AN ORB or 3/8 NPT port, then you can use a direct mount damper, FOUND HERE. What is an ORB port? CLICK HERE

Radium Direct-Mount pulse dampers mounted on fuel rails

If the fuel rail does NOT have a compatible port, then an in-line damper should be used, FOUND HERE. The inline damper should be located on the fuel feed line, within the vicinity of the fuel rail, but exact placement is not critical.

If an engine has two fuel rails (V8, V6, H4, etc) it is not always necessary to install a damper on each rail. However, testing will have to be done to verify. In most cases a single damper is sufficient.

In-Line Fuel Pulse Dampers

Can I use adapter fittings to fit a Radium fuel pulse damper?

If a fuel rail does not have a compatible port, adapter fittings can be used without sacrificing the function of the pulse damper. Note that Radium Engineering offers fuel rails for all popular engines (and even some unpopular ones!) that have ports for an FPD.

How many dampers do I need?

In most cases, just one. However, special cases may require more. This will take experimenting, as each fuel system is different and pulse damping is complex and not intuitive. For example, OEMs may place a damper near the fuel pump outlet, multiple on the fuel rail(s), and even on the return line in order to make sure that the system is as pulse-free as possible. This is not entirely necessary on a modified high-performance vehicle, as the needs of a performance car are different than a mass produced passenger car.

If an engine has two fuel rails (V8, V6, H4, etc) it is not always necessary to install a damper on each rail. However, testing will have to be done to verify. In most cases a single damper is sufficient.

What about the vacuum reference port on the Radium Dampers?

The vacuum reference port on the damper should ONLY be hooked up to the intake manifold if the fuel pressure regularily exceeds the maximum pressure for the damper. This is 70psi for the FPD-R and 105psi for the FPD-XR.

This can happen on boosted vehicle with 1:1 rising rate pressure regulator.

If fuel pressure does not exceed the upper range values, then a vacuum reference is not needed and the port on the damper can be plugged with the included screw.

Reference the FPD install instructions for more details.