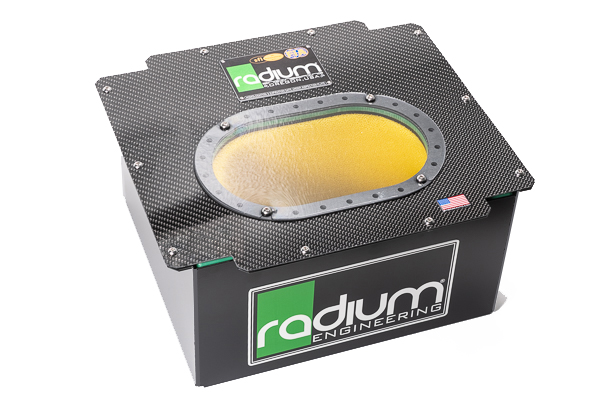

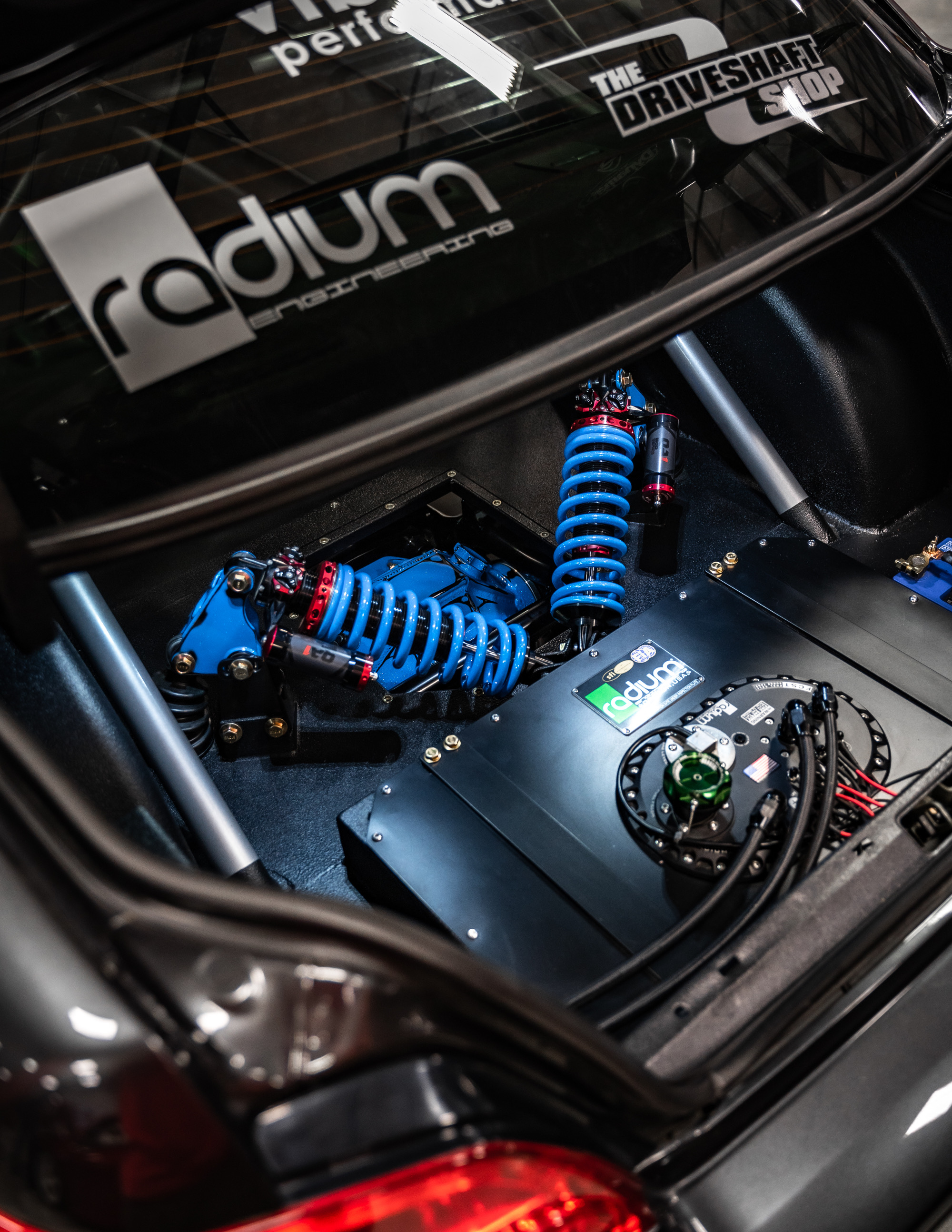

Radium Engineering's flagship fuel cells are a popular fuel storage choice for motorsports enthusiasts all around the world. From drifting to off-road, Radium fuel cells have proven to be the go-to solution.

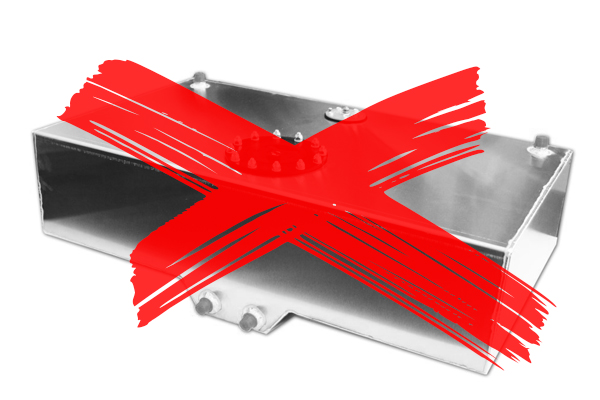

What isn't a Fuel Cell?

Many consider a sheet metal constructed fuel tank a fuel cell, when in fact a proper motorsports fuel cell is more complex. There are many "welded boxes" on the internet claiming to offer the benefits of a fuel cell, when in fact, they do not.

There are a few problems with welded metal tanks. A basic aluminum, stainless, or mild steel fabricated tank is more susceptible to fracturing in the event of a collision. This would create leak(s) and could lead to a dangerous fire situation. Even a minor fender bender, or the flexing of the chassis during hard driving could create enough force to distort and crack the metal container. Fuel weighs about 6.5 lbs per gallon. With a 14 gallon fuel cell that is 91 lbs of fuel sloshing, flexing the walls, and applying strain to the welds. When that much weight is subject to g-loading, the resulting forces are very large and can damage even a well-designed metal fuel tank. A cracked welded tank

A cracked welded tank

Furthermore, fluctuating fuel temps, exhaust heat, and variable ambient temperatures put excessive thermal expansion stress on the tank. Lastly, chemical compatibility, weld quality, and corrosion are also concerns when using a metal container for fuel storage. In short, Radium Engineering does not recommend welded sheet-metal fuel tanks on performance vehicles.

Fuel cells used in motorsport racing often require FiA or SFI certification to ensure safety requirements are met. The guide below helps explain how real fuel cells work and why certification is necessary.

What is a Fuel Cell?

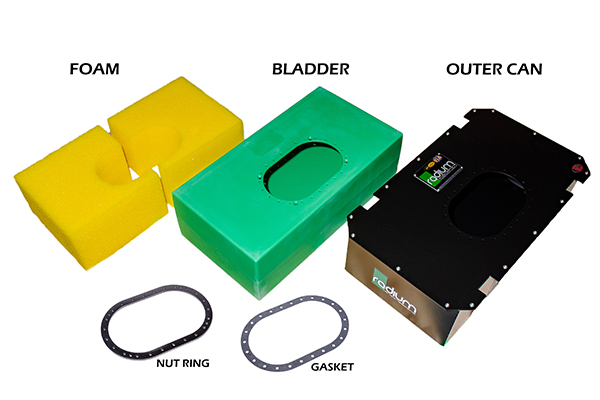

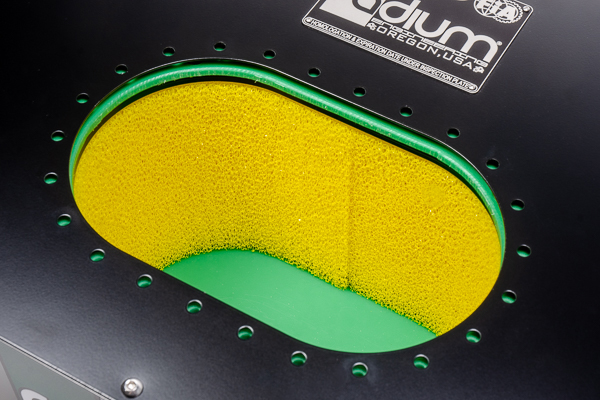

As shown, motorsports-grade fuel cells are generally comprised of three components as shown below: the outer shell (enclosure or can), the bladder (where fuel resides) and the foam baffling.

Radium Engineering fuel cell enclosures are made from lightweight aluminum, but other brands may use steel or other materials. The enclosure is the first line of defence, protecting the bladder from UV degredation and other small sources of puncture. This layer is similar to the construction of a helmet; the hard outer shell aids slightly in safety, but is not the most critical part.

Radium Engineering fuel cell enclosures are made from lightweight aluminum, but other brands may use steel or other materials. The enclosure is the first line of defence, protecting the bladder from UV degredation and other small sources of puncture. This layer is similar to the construction of a helmet; the hard outer shell aids slightly in safety, but is not the most critical part.

FIA and SFI specifications do not cover the outer can material alloy or thickness, only the internal fuel bladder. Other governing bodies require a certain outer can thickness. For instance, SCCA requires a fully enveloped enclosure comprised of 0.036” steel or 0.059” aluminum.

The fuel cell bladder is the most important part. The bladder must be resilient against impacts, punctures, and tears. The material also needs to be flexible enough to prevent cracking or fuel leakage in the case of impact and thermal expansion. These requirements have led to the development of different high-tech bladder materials used in the industry. Radium Engineering chose to only focus on molded polymer bladders as they have the best chemical compatibility and still meet all the structural testing requirements put forth by SFI and FIA.

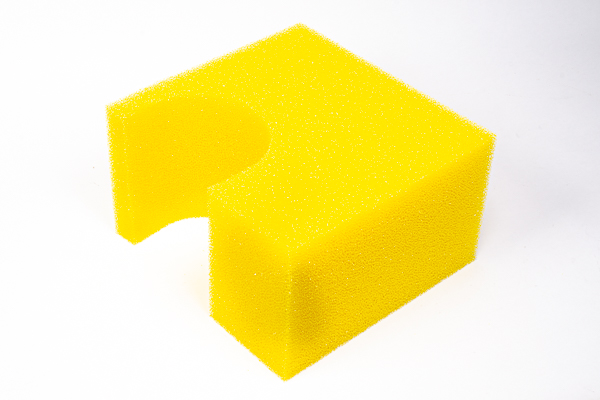

The foam baffling is required per FIA FT-3 specification. It is essentially a large open-cell sponge inside the fuel cell and serves several purposes. It serves as a device to prevent fuel vapor build-up inside of the cell and it also helps prevent fuel slosh which can cause fuel starvation. Fuel cell foam is a wear part and should be inspected periodically to ensure integrity. Loss of elasticity or degradation of any kind are signs the foam should be replaced.

What are FIA and SFI?

The Federation Internationale de l’Automobile (FIA) is based in Europe and has been around for over a century. It is an huge international organization that promotes road safety around the world and creates rules and regulation governing all forms of motorsports. FIA's most prominent role is licensing and sanctioning of Formula One, World Endurance Championship, World Rally Championship and various forms of sports car and touring car racing.

For the safety of the driver, FIA homologation (certification) is required in many forms of racing. This covers many safety related components, including fuel cell bladders. FIA has a few distinct classifications regarding fuel bladders: FT3, FT3.5, and FT5. There are other standards required by other sanctioning bodies, but FIA is the gold standard.

Check with your sanctioning body to see what requirements your vehicle must meet.

The SFI Foundation is a US-based non-profit organization that sets safety standards for motorsports equipment. They have specific testing required to obtain certification. Regarding fuel bladders, if a bladder meets FiA standards it automatically meets all requirements by the SFI Foundation. Radium Engineering went the exta step and persued certifications by both organizations to ensure the best product possible.

Check with your sanctioning body to see what requirements your vehicle must meet.

Radium Engineering Testing and Quality Control

In order to obtain cetifications, bladders must be subject to rigorous mechanical testing including: tear, puncture, tensile, and compression testing per FIA and/or SFI requirements.

Even though certifications have been achieved, Radium Engineering still inspects and quality tests every single fuel bladder before it is approved for use in a fuel cell.

Expiration

Heat cycling, UV light, abrasion, and chemical-induced breakdown are all factors that contribute to elastomers breaking down in a bladder. Alcohol fuels can also cause deterioration because of the water absorbtion and resulting acidic mixture. Fortunately, all Radium Engineering bladders are made from a special polymer that are not as susceptible to chemical deterioration like coated fabric bladder variations that are glued together.

Regardless of the fuel cell design, certifications expire 5 years from the date of manufacture. Check the label on the fuel cell bladder for the expiration date. After this date, the bladder must be replaced with a new one in order to renew the certfication. Radium Engineering does not offer re-certifications on used bladders.

NOTE: The fuel bladder may still be usable even after expiration is expired.

Learn More

Radium Engineering fuel cells are one component of a comprehensive fuel delivery system. Watch the video below to learn more about fuel cell configuration, setup and optional accessories.

Conclusion

To conclude, metal box style "fuel cells" are prevalent on the discount market, however, they offer little to no engineered protection in regard to safety. The added cost of a certified bladder-style fuel cell can be easily justified in the event of a collision or other disaster.